The robotics industry is experiencing exponential growth, fueled by advancements in artificial intelligence (AI), machine learning (ML), and automation. From industrial manufacturing to medical applications and even personal assistive devices, robots are becoming increasingly integrated into our daily lives. A crucial component underlying robotic functionality is the motor, and within the realm of motor technology, gear motors hold a pivotal position. This article delves into the fundamental principles of gear motors, analyzes their performance characteristics, and compares different types, highlighting the role of precision and efficiency in modern robotic systems – a particularly relevant topic given the current focus on sustainable and energy-efficient technologies.

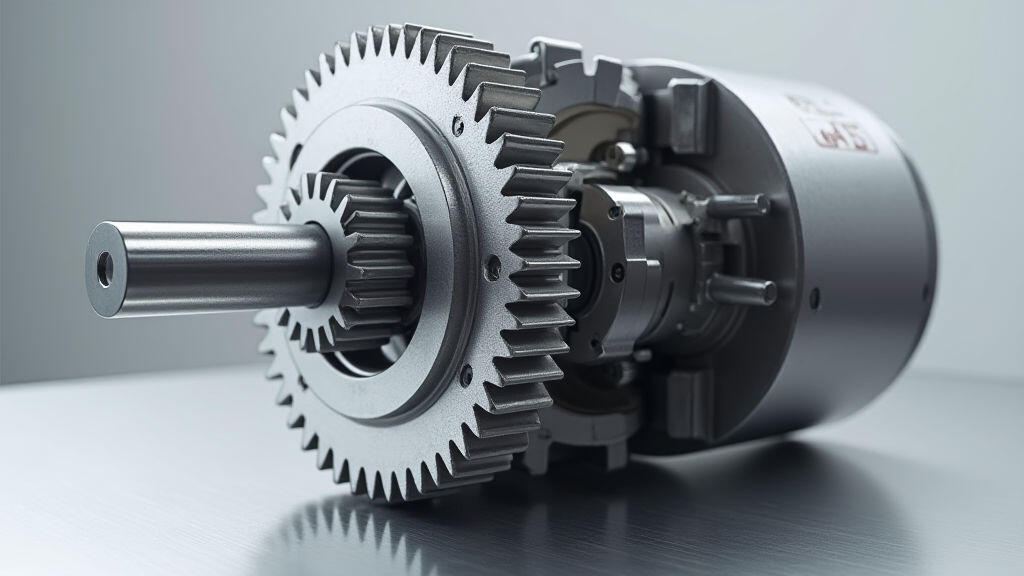

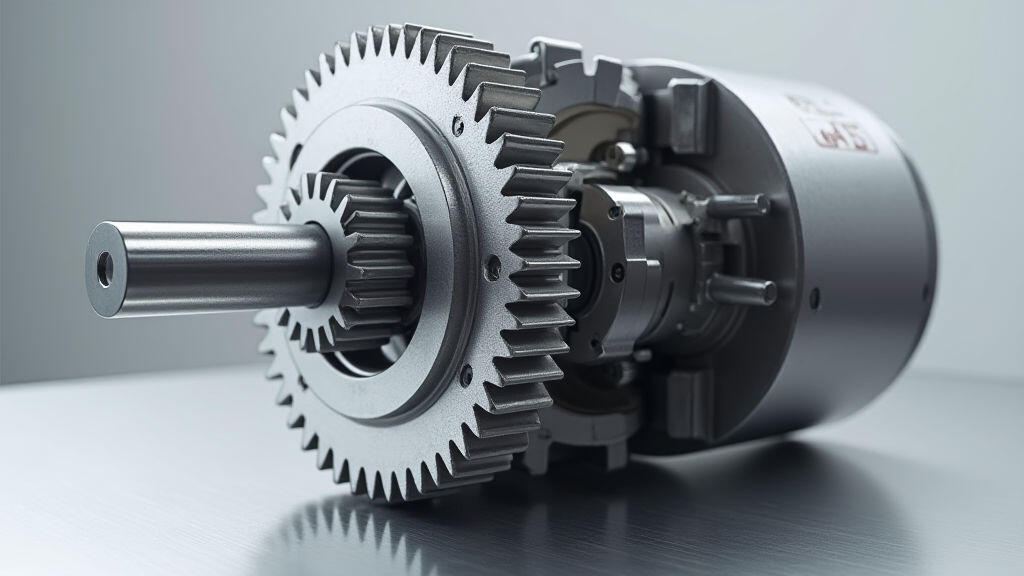

At the core of any gear motor's operation lies the principle of mechanical advantage. This concept, rooted in Newtonian mechanics, allows a smaller, high-speed motor to drive a larger, lower-speed output shaft. The gears within the motor multiply the torque, resulting in increased rotational force. This torque multiplication is essential for robotics, where powerful and controlled movements are paramount.

There are several primary types of gear motors, each with its own advantages and disadvantages:

Evaluating the suitability of a gear motor for a robotic application requires a thorough understanding of several key performance metrics:

Performance Comparison Table (Example Values):

| Motor Type | Torque (Nm) | Speed (RPM) | Efficiency (%) | Backlash | Application Example |

|---|---|---|---|---|---|

| Spur Gear | 0.5 - 5 | 1000 - 5000 | 65 - 80 | 0.1 - 0.5 mm | Simple robotic arms, conveyors |

| Planetary Gear | 1 - 100+ | 100 - 1000 | 75 - 90 | 0.05 - 0.3 mm | High-performance robotic arms, industrial robots |

| Helical Gear | 0.8 - 20 | 500 - 2000 | 70 - 85 | 0.1 - 0.4 mm | Robotics requiring smooth operation, medical robots |

| Worm Gear | 0.1 - 1000+ | 5 - 100 | 50 - 70 | 0.05 - 1.0 mm | Precision positioning systems, automated valves |

The rise of sophisticated robotic systems, especially those driven by AI and ML, demands motors with exceptional precision and efficiency. Consider the context of current global events – the increasing emphasis on sustainability and energy independence. Robotics, being an energy-intensive field, is under pressure to adopt more efficient motor technologies.

For example, advancements in AI-powered robotic surgery require motors capable of extremely precise movements with minimal vibration and noise. Similarly, autonomous delivery robots benefit from high-efficiency gear motors that extend battery life and reduce operational costs. MES-Drive has been at the forefront of developing high-efficiency planetary gear motors specifically tailored for these applications. Their motors utilize optimized gear designs and advanced lubrication techniques to minimize energy losses.

Further, the increasing sophistication of path planning algorithms necessitate motors with low backlash to ensure accuracy in following programmed trajectories. This is especially true in applications like collaborative robots (cobots) working alongside humans. The safety of human-robot collaboration depends on the reliability and predictability of the robot's movements, which is directly linked to the performance of the gear motor.

The future of gear motors in robotics is focused on several key areas:

In conclusion, gear motors are indispensable components in the robotics field, enabling precise and powerful movements crucial for a wide range of applications. The choice of gear motor type depends heavily on the specific requirements of the robot, considering factors like torque, speed, efficiency, and size. As the robotics industry continues to advance, driven by innovations in AI and a growing emphasis on sustainability, the demand for high-performance, energy-efficient gear motors will only intensify. MES-Drive is poised to meet this demand with its innovative product line, providing solutions that power the next generation of robots and contribute to a more efficient and sustainable future. The push for energy-conscious robotics, particularly resonant with global climate initiatives such as the Paris Agreement, positions advancements in motor technology like MES-Drive’s as vital and strategically important.

Leave A Reply

Your email address will not be published. Required fiels are marked